What’s in Availability Workbench?

AWB integrates updated versions of the AvSim+ (Availability Simulation Software) and RCMCost (Reliability Centered Maintenance) products. These products have been used in industry since 1988. Availability Workbench also includes a brand-new life cycle cost analysis module.

Availability Workbench provides a fully integrated environment for:

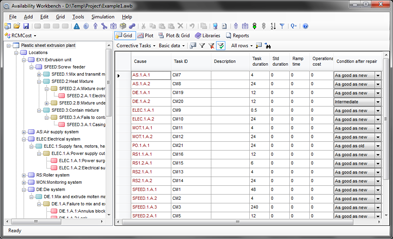

- Reliability Centered Maintenance. Developing and maintaining a Reliability Centered Maintenance (RCM) program to optimize your reliability and maintenance strategy.

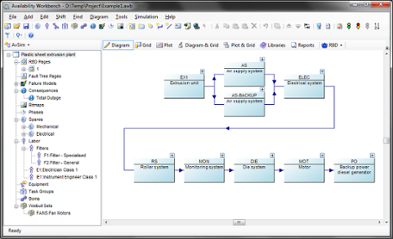

- Availability Simulation. Performing full system availability predictions taking into account complex dependencies on spares and other resources.

- Life Cycle Cost Analysis. Performing a Life Cycle Cost Analysis to calculate the expected costs of your system during its lifetime.

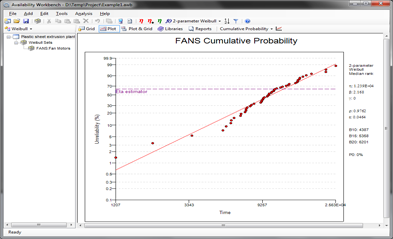

- Weibull Analysis. Analyzing historical failure data to model the failure characteristics of equipment.

- SAP Interface. The AWB SAP Interface allows you to transfer data between AWB and SAP.

How can Availability Workbench Help Me?

Availability Workbench can help answer questions such as:

- Is planned maintenance cost effective? How often should it be performed?

- What design improvements are cost and safety effective?

- What is the optimum level of spares to be held on site and at a depot?

- How can labor and equipment usage be improved?

- How can buffers best be employed to maintain capacity?

- How can risk be reduced?

- What are the likely life cycle costs?

- What is the best frequency for performing major overhauls?

- Is predictive maintenance worth doing?

- How do aging assets affect life cycle costs?

Isograph's Availability Workbench™ modules